PLASTICS

Expertises

Testing and Trials

Laboratories and Instruments

Projects

- Development of new formulations for thermoplastic polymers

- Process optimization for the transformation of plastic materials

- Eco-friendly resin development from bio-sourced biodegradable polymers

- Use of eco-friendly processes (reactive extrusion)

- Valorization of recycled plastics

- Development of functional polymer material

- Preparation of innovative fillers for functionalization or strengthening of thermoplastic resins

- Development of polymer material for additive manufacturing (composite and nanocomposite thermoplastics, photosensitive resins, polymer binders, etc.)

Technical Support Services

- Additive manufacturing

- Failure analysis

- Reverse engineering

- Qualification analysis

- Valorization of plastics and circular economy

- Numerical simulation (FEM/FEA)

- Process validation

Materials

- Polymer formulation

- Laboratory tests and trials

- Physicochemical characterization of polymers

Product Design

- Material selection

- Failure analysis

- Design (CAD)

- Quality assurance (QA)

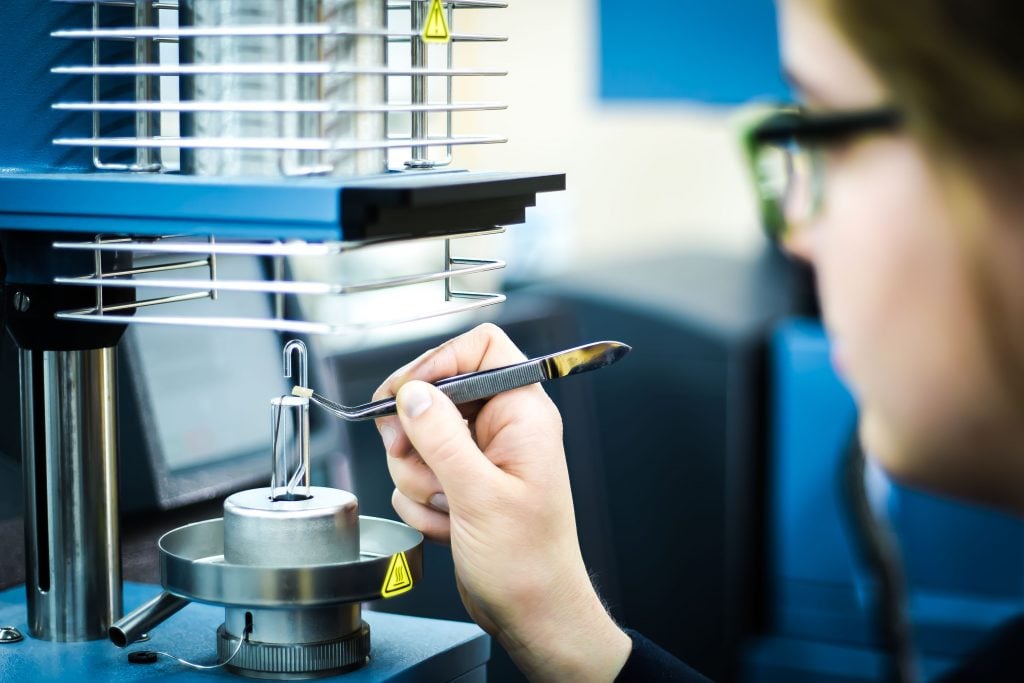

Mechanical and Thermomechanical Characterization

- Tensile strength, bending and compression Mechanical analysis

- Impact (Izod, Charpy, Gardner, etc.)

- Dynamic mechanical analysis (DMA)

- Thermomechanical analysis (TMA)

- Stress crack resistance (ESCR, NCLS)

- Tear resistance

- Thermal expansion coefficient (TMA)

Implementation and Manufacturing Processes

- Optimization of processes and resolving industrial issues

- Industrial Scale-Up

- Transformation, assembly and finishing

Physical Characterization

- Density/specific gravity

- Hardness (Rockwell, Shore, Barcol)

- Friction coefficient

- Water absorption

- Permeability (O2 and water vapour)

- Colour, brilliance, transparency

- Abrasion and scratches

Transformation Processes

- Twin screw extrusion

- Injection moulding

- Thermoforming

- Extrusion blow moulding

- Extrusion – calendering

- Extrusion – coating

- Filament extrusion

- Compression moulding

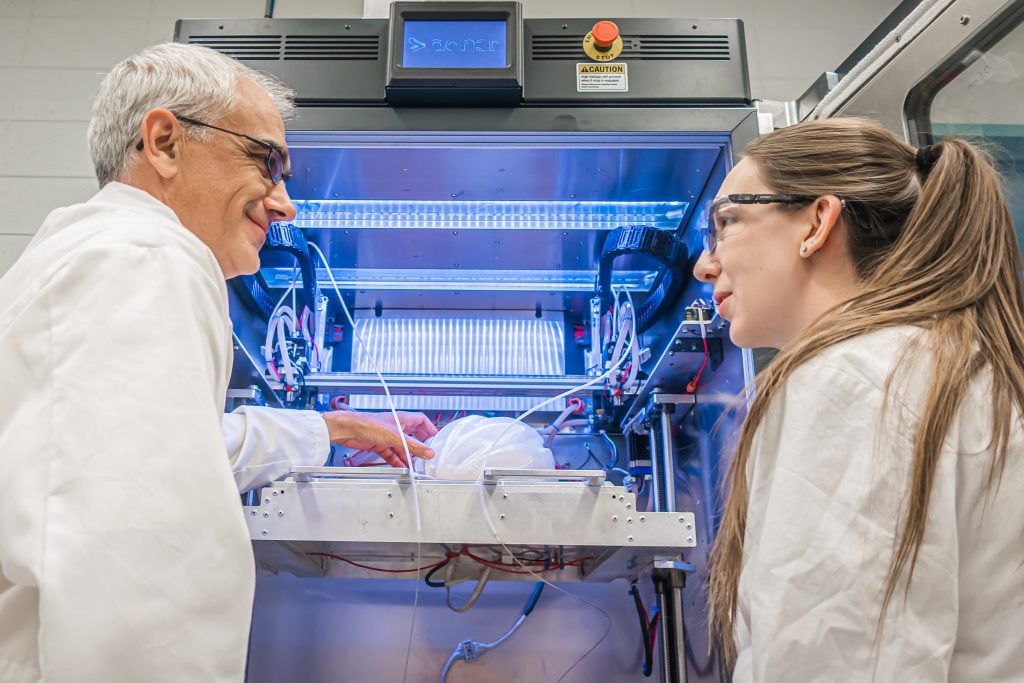

- Additive manufacturing processes (FDM, SLS, SLA, CLIP)

Thermal Characterization

- Differential Calorimetry Analysis (DSC)

- Thermogravimetric Analysis (TGA)

- Heat distortion temperature (HDT)

- Vicat softening point (VST)

- Flammability measurement

- Thermal conductivity

Rheological Characterization

- Melt flow index (MFI)

- Viscosity (Brookfield, inherent, complex)

- Rheometry

Aging and Degradation

- Accelerated aging (UVA, UVB, Xenon)

- Climate conditioning (environmental chamber, salt spray)

- Chemical resistance

Chemical Analysis

- Chemical composition analysis (XRF)

- Ignition loss, ash content and ash analysis

- Chemical resistance

Spectroscopic and Microscopic Analysis

- UV-visible microscopy (UV-Vis), Fourier Transform InfraRed spectroscopy (FTIR) and Raman

- Optical microscopy (polarized light [POM], phase contrast, according to temperature)

- Optical microscopy combined with Raman spectroscopy

- Scanning Electron Microscope (SEM) combined with Energy Dispersive Spectroscopy (EDX)

Additive Manufacturing

- Advanced additive manufacturing for future vertical take-off devices.

- Creation of concept demonstration strategies and hybrid manufacturing for tools – Polymer thermoplastics axis.

- Processing of recycled nylon powder for additive.

- Development of filaments made from high-performance thermoplastics and reinforced with fibres for 3D printing of parts used for the transport industry and in high temperature composite tools.

Biodegradable and Bio-sourced Polymers and Bio-composites

- Development of bio-renewable polymers for the plastics and composite industry.

- Production of a new agricultural mulch: Phase 2 – optimization, performance validation and industrial transfer.

- Development of a bio-sourced formula for cardboard paper coating.

- Development of environmentally friendly thermoplastic composites for the automotive industry from cellulose fibres.

- Development of a marine cellulose-biopolymer material using surface treatment techniques for cellulosic products.

Formulation

- Using innovative technical specifications for polymers.

- Study of durability and mechanical performances of HDPE-based hybrid materials: application to the valorization of recycled polymers used in water pipes.

Recycling

- Recycling of tubing and accessories used in the production of maple products.